Filling

Filling

SHOW ME THE FLOW!

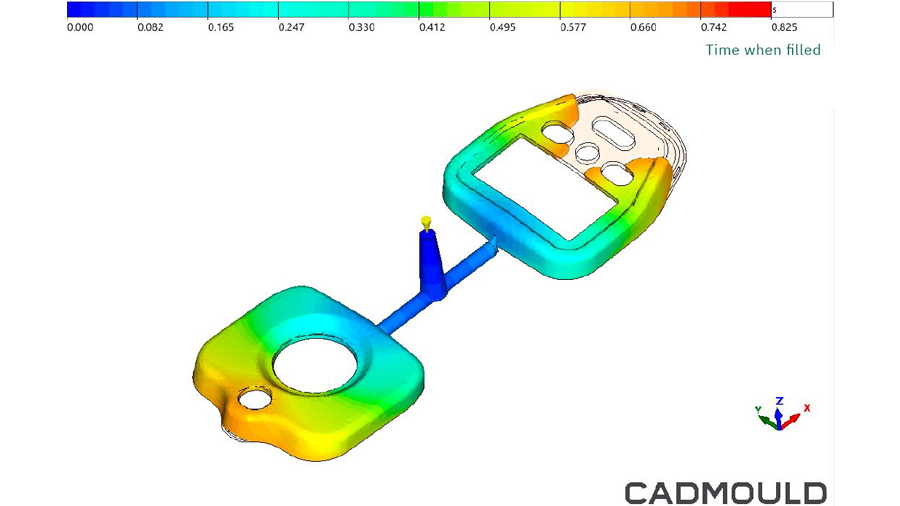

CADMOULD FILL is our foundational module. It simulates the filling behavior, as the melt flows into the cavity. Part and mold designers use CADMOULD Fill to anticipate and improve filling behavior

RESULTS

- CADMOULD Fiber computes the following results:

- Filling of the part

- Pressure distribution

- Temperatures

- Flow speeds

- Clamping forces during filling (for clamping forces in the packing pressure and cooling phase, the Pack module is additionally required)

- Forces on sliders during filling

- Weld lines

- Air inclusions and venting

- Cooling time estimation

- Shot volume

- You can view these results in 3D, as a cross section, as an animation across time, or as diagrams.

BENEFITS

- Here are some of the things plastic injection molding professionals can achieve using CADMOULD Fill

- Optimal design of your part’s filling

- Optimized design of hot and cold runner systems

- Determine suitable gating positions automatically, and balance gating systems

- Adjust gating systems, as well as part wall thicknesses, directly in CADMOULD, without needing to go back to CAD

- Design multiple-cavity molds

- Achieve a better first-time right rate, reducing sampling time and material waste, since the parameters of the filling phase are already known and optimized. Reduce costly mold corrections. This results in significant time and cost savings.

- The simulation results enable you to discuss options, advantages and disadvantages with your customers and colleagues

- In this example, you can see a weld line and an air entrapment forming in the center of the part. CADMOULD Fill enables you to predict this before the mold is built, and explore options to solve it. In combination with our Cascadic Injection module, you can also model sequential opening of gates.

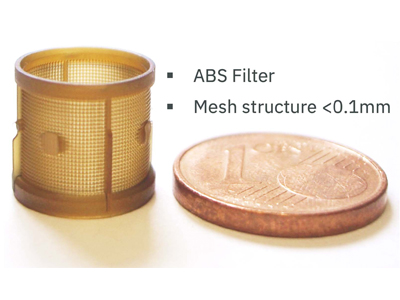

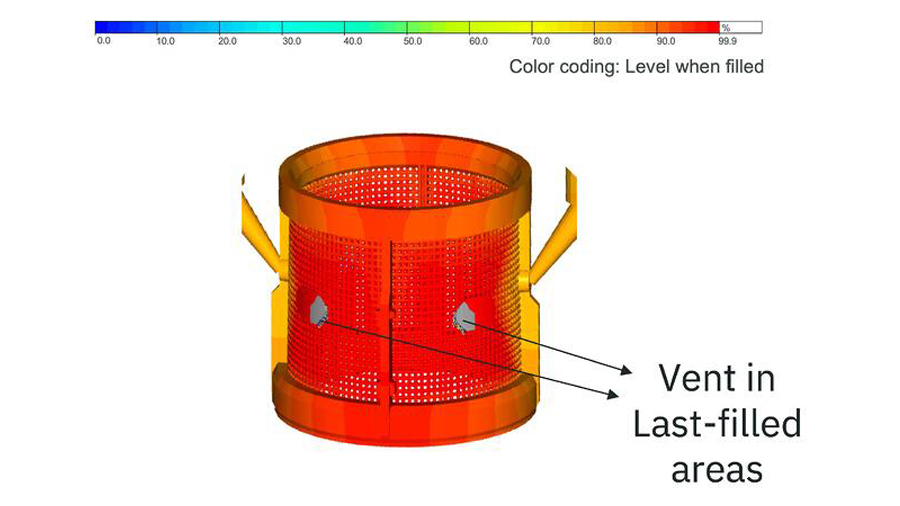

Where to vent this ultra-fine filter structure?

CADMOULD’s filling simulation was used to find the last-filled areas in this very finely meshed part (mesh size 0.1mm). Vents were placed here in order to avoid air entrapments and thereby avoid holes in the filter mesh structure.

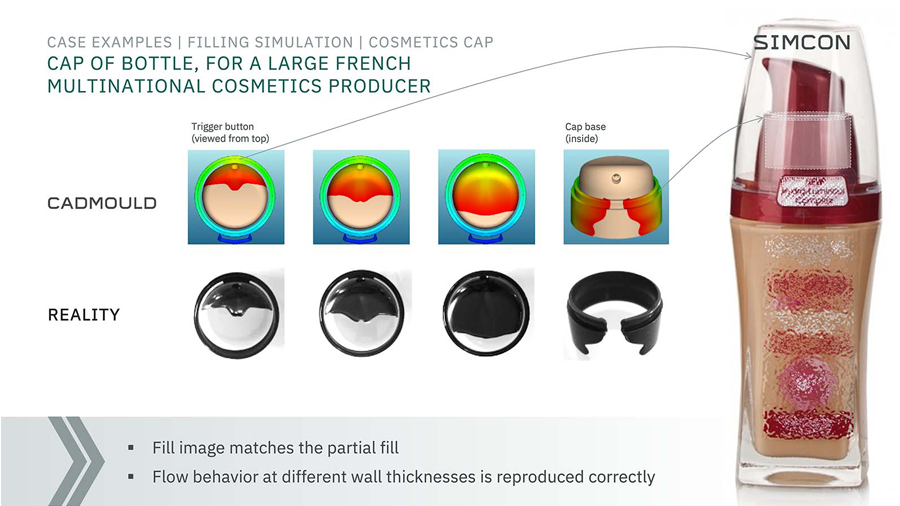

How to ensure weld lines are not in visible areas?

CADMOULD was used to simulate the filling of the bottle cap of this cosmetics bottle. The goal was to make sure that weld lines form only in areas that are invisible. The filling simulation matched reality perfectly.

How to balance the filling in a multi-cavity mold?

CADMOULD Fill enables you to check whether your cavity, runner and injection process will result in a balanced filling, or not. If you see issues, you can test alternative gate diameters and pressure settings, to improve results.